Apr 2024 – The operation of a chiller in a cold climate has its own set of guidelines to follow. The climate in your area will be a major factor in how well your chiller operates. The conditions in your area should be seriously considered when buying a new chiller.

The most important thing to remember is a yearly maintenance check before the winter months arrive. There is nothing worse than having a problem arise out of no where when it is already too late to deal with it properly.

Glycol

If you plan to buy a chiller or you already have one working in a cold climate, make sure that the chiller is using the right mixture of water and glycol. When the glycol percentage in the coolant isn’t high enough, the water will freeze which can cripple your system, causing hundreds, if not thousands of dollars of damage to your system and your bottom line.

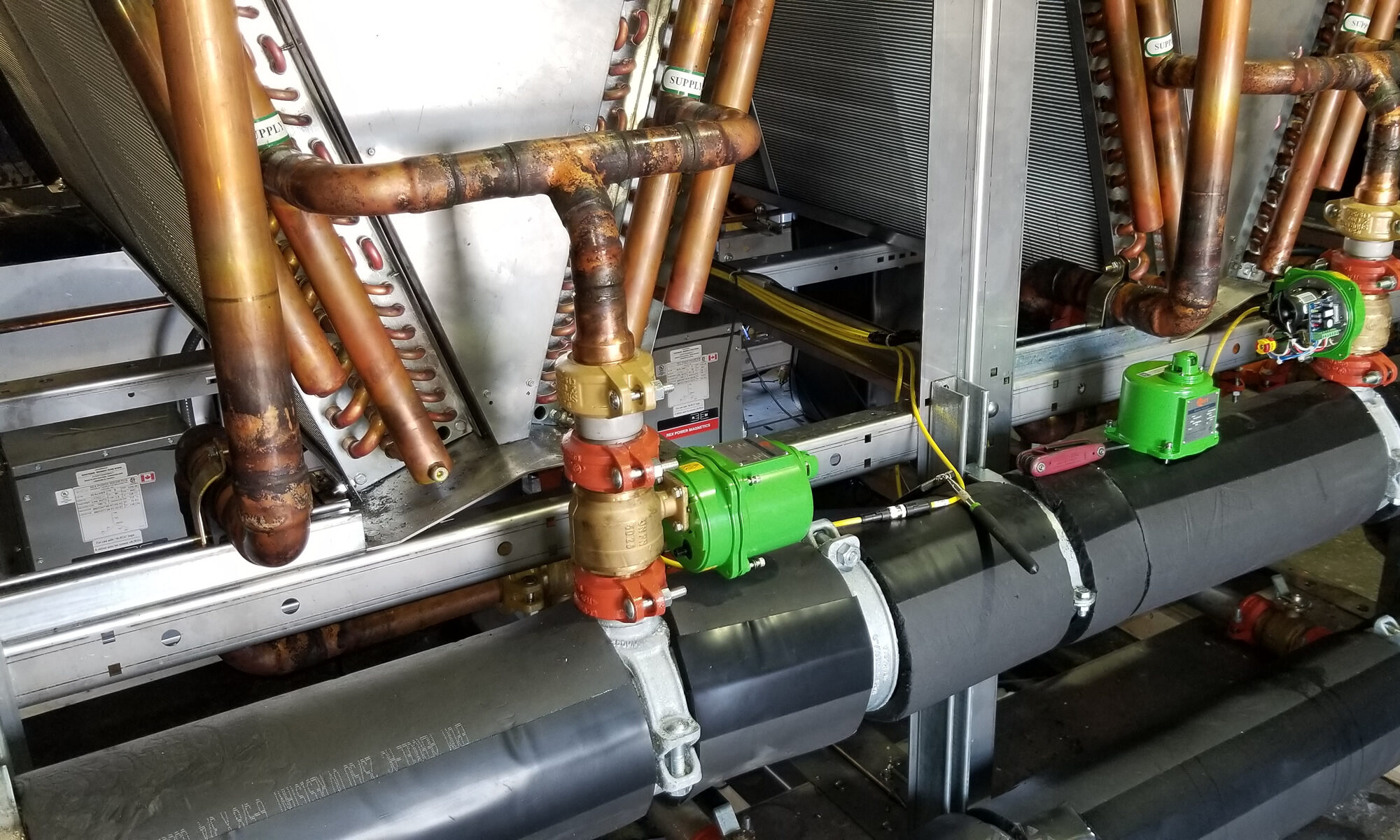

Clean Components

Chillers are made with several components that are already susceptible to debris and damage, even when the weather is perfect. This can only get worse in a colder climate. Ice and snow can combine with existing dirt and debris to clog components, such as your chiller’s condenser, causing expensive interruptions in production. This nightmare can be avoided by cleaning the condenser coils on a regular basis.

Head Pressure Drops

Head Pressure drops in cold weather are another potential problem that you will want to avoid at all costs. These head pressure drops are easily avoided if your chiller is equipped with low ambient controls like fan cycling. Make sure that your chiller is properly equipped to handle extremely cold temperatures.

Keep The Pump Running

Some of the most costly breakdowns can occur when the chiller is shut down over night. When the chiller is running, the process itself will provide enough warm water to keep coolant mixture above freezing temperatures. When the chiller is shut down at night or is stopped for a long period of time, the ambient air temperature can cause the water to freeze. By allowing the pump to run, you will not only add heat from the pump itself but from inside the building as well. Moreover, moving water takes a lot longer to freeze than stagnate water.

Have A Plan

It goes without saying that it’s a good idea to plan ahead or plan to fail. Make sure you chiller has the right components to handle the cold weather. Schedule regular maintenance checks especially some time late in the fall before winter arrives.