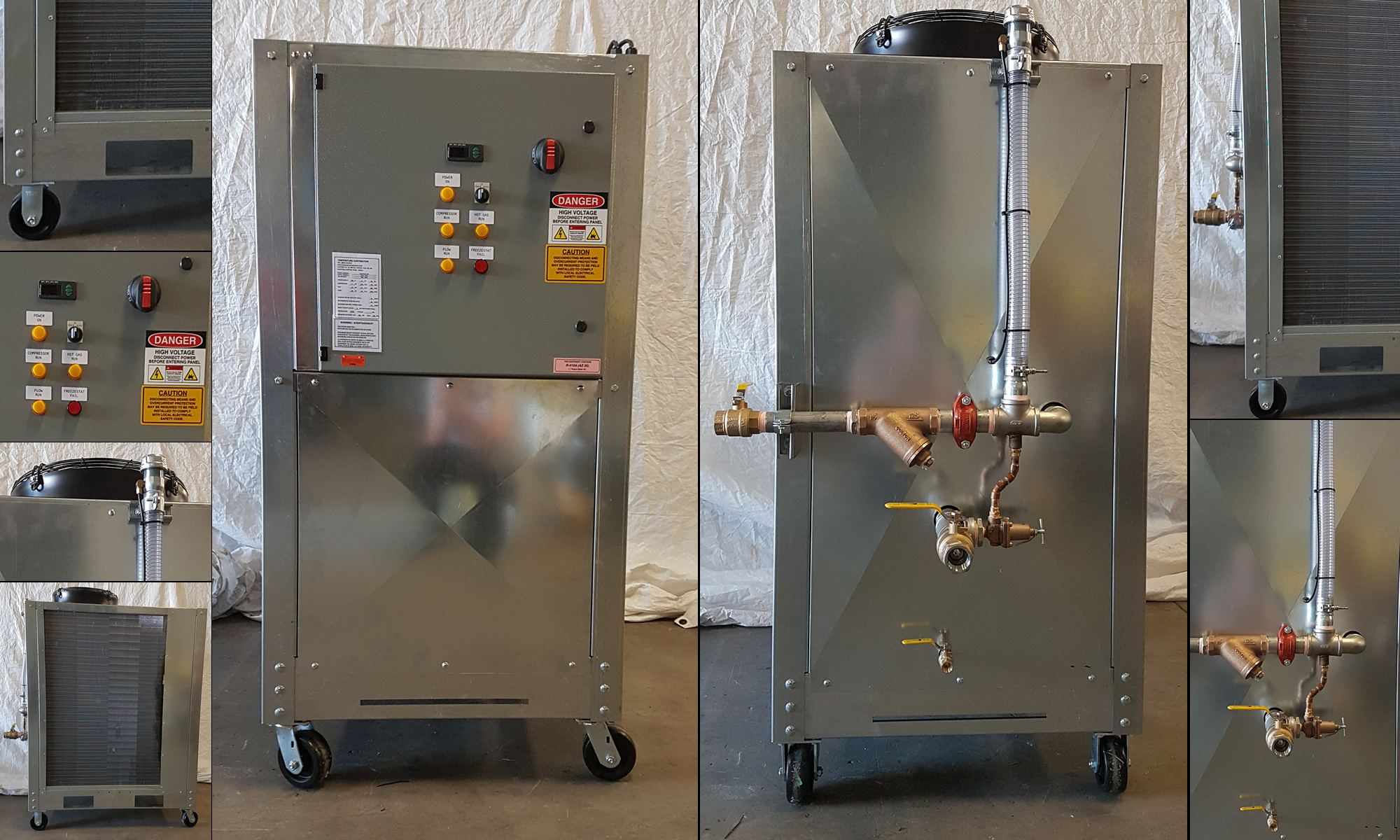

Temperature Corporation manufactures air cooled portable chillers: the Standard Series ACP–3SZV-SP to ACP-20SZV-SP single compressor chillers and the ACP–10DZV-SP to ACP-30DZV-SP dual compressor and dual refrigeration circuit chillers.

Our standard series of air cooled portable chillers can be moved from one piece of process equipment to another using casters. The standard air cooled portable chiller is a mid-sized model that offers medium capacity cooling of 5 tons to a maximum of 30 tons at 50° F leaving water temperature at 95° F plant air temperature. Temperature range is from 20° F (-6.6° C) to 70° F (21° C) leaving water or water/glycol temperature.

- With 11 models to choose from.

- 2 YEAR parts warranty on the whole chiller.

- Our unique design has the components accessible for inspection, maintenance and service.

- Single Scroll compressors up to 20 hp.

- Dual compressors from 10 hp up 30 hp.

- Our chillers come standard with hot gas by-pass for capacity control.

- For freeze protection we include both a water flow switch and a freeze thermostat.

- Stainless steel frame, tank and pump up to 5 hp, cast iron pump from 7.5 hp and up.

- Stainless steel brazed plate evaporator for cooling, not an inefficient coil-in-tank which is very difficult to repair and extremely expensive to replace

- NEMA / EEMAC Type 4/12 Control Panel.

Main Features

COMPRESSOR

The standard air cooled portable chiller comes with a single scroll compressor up to 20 tons and dual compressors up to 30 tons and comes with a hot gas by-pass for two (2) steps of capacity control, 100%, 50% and off for the single compressor and four (4) steps of capacity control, 100%, 75%, 50%, 25% and off for the dual compressor.

Optional two stage compressors with hot gas for 3 steps of capacity control on the single compressor chiller and 6 steps with dual compressors. Digital compressors from 100% to 20% full load.

EVAPORATOR

The evaporators are single circuit up to 20 hp and dual circuits from 10 hp up to 30 hp with 316L stainless steel copper brazed plate chiller vessel with a water outlet freeze thermostat, water flow switch and return line bronze “Y” strainer.

CONDENSER

The condensers are indoor air cooled with copper tubes and aluminum fins one for each compressor (circuit) with a single top discharge propeller fan up to 15 hp and dual top discharge fans up to 30 hp. Fans are direct coupled to the fan motors.

TANK

The all welded tank is fabricated from 14 gauge stainless steel complete with 3/4″ closed cell thermal insulation tank with a 1¼” clear plastic water fill – level – vent tube with vented cap, side bottom drain with shut-off valve and return line strainer with shutoff valve. Tank capacity ranges from

20 gallons to 90 gallons

PUMP

The standard model comes with a stainless steel pump up to a 5 hp and cast iron from 7.5 hp and up, all are close coupled to a 3500 rpm TEFC motor. Pumps complete with non-ferrous piping and a bronze suction shutoff valve, suction and discharge fittings for pump removal, a bronze discharge check valve and flow control shutoff valve and a pump discharge pressure gauge with shutoff valve.

Optional available are discharge water pressure operated by-pass valve to maintain flow, 1750 rpm pumps for low pressure operation and higher pressure pumps.

CONTROLS

The controls consist of a two (2) stage thermostat for single compressors with refrigeration high and low pressure safeties, run and fail lights and compressor and fan motors internal thermal overload protection in winding.

Dual compressor chillers have a “chiller controller” with door mounted key pad display with high and low pressure sensors, chilled water in and out temperature sensors, freeze fail, flow fail and compressor internal protector.

FREEZE PROTECTION

The standard single compressor chillers uses both a flow switch and a freeze thermostat.

COMPONENTRY

Other notable components include a refrigeration expansion valve, sight glass moisture indicator, filter dryer, liquid line solenoid with shutoff valve, a hot gas solenoid with shutoff valve and a compressor crankcase heater.

ELECTRICAL CONTROL PANEL

NEMA 4/12 (EEMAC 4/12) control panel with through-the-door non-fused disconnect, compressor and pump three phase fuses, compressor motor contactor, pump motor starters, control voltage transformer with primary and secondary fuses, power on, run and fail lights, two stage thermostat or chiller controller are ESA or CSA approved at our plant and shipped with label.

FRAME

Chiller base frame is fabricated from 12 ga. stainless steel bolted frame with galvanized steel panels and 2” wide x 5″diameter casters: two swivel and two rigid.

VOLTAGE

All models 230/460/575V, 3 phase, 60 hertz and 380V, 3 phase, 50 hertz.